Last Sunday’s Chicago Handmade Bicycle Show foregrounded the question of whether Chicago cyclists – both commuters and hobbyists – are ready to embrace the locally made bicycle movement that’s already blossoming in other bike-friendly cities.

Chicago’s the nation’s third-largest city, and infrastructure like our 20-plus miles of protected bike lanes, 6,000 Divvy bike-share vehicles, and The 606 elevated greenway helped us win Bicycling Magazine’s award for best U.S. cycling city last fall. Yet we only have a handful of custom bike builders, putting us far behind other, much smaller cycling Meccas in this department, such as San Francisco, Seattle, Portland, and even Minneapolis.

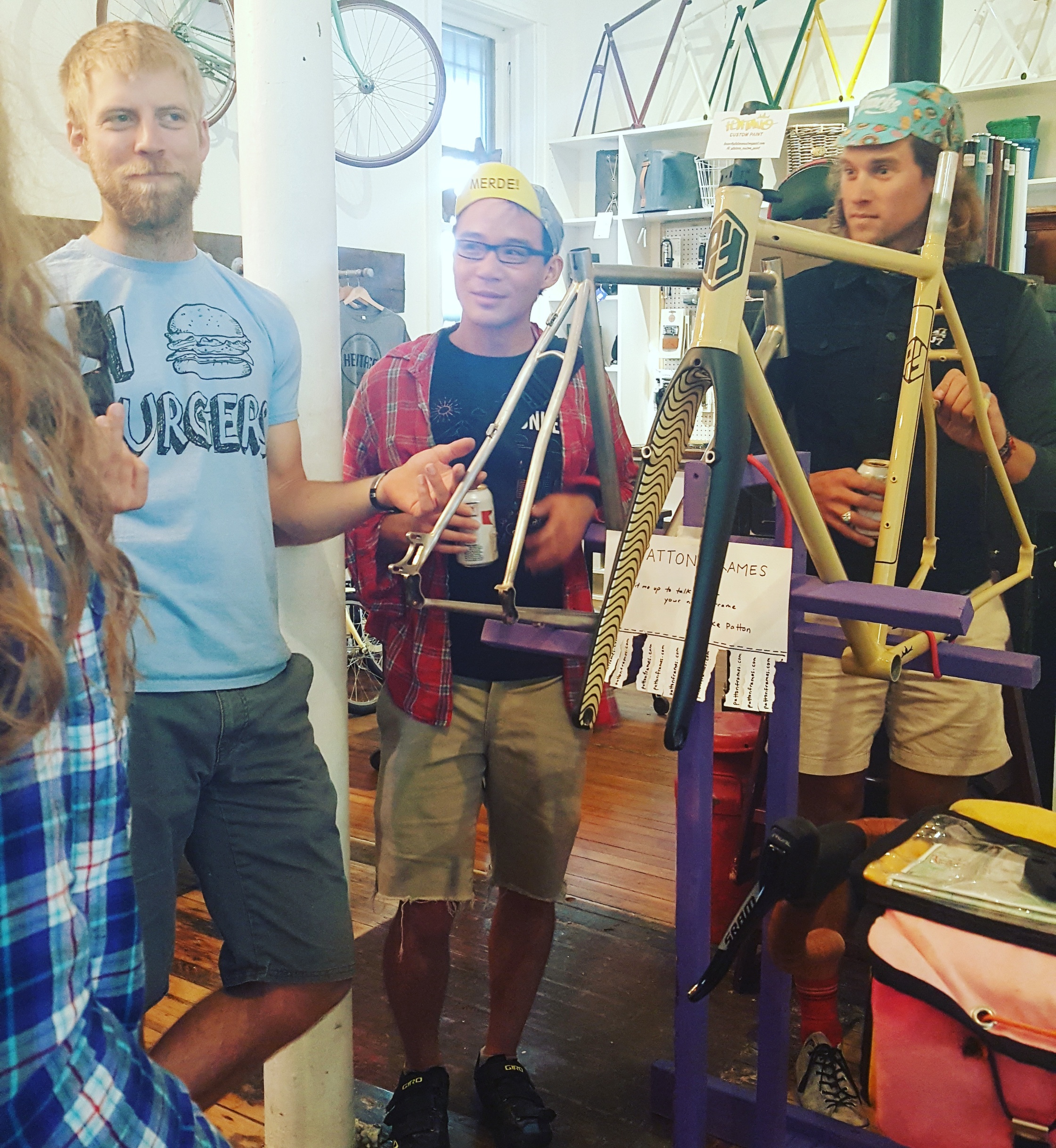

Sunday’s event, held at Heritage Bicycles, a bike shop/café in Lakeview that sells its own locally made rides, showcased frame builders from Chicago and other nearby Midwestern cities, and doubled as a family reunion of sorts for the craftspeople. Exhibitors included Humble Frameworks, Legacy Frameworks, Pachyderm, Patton Frames, Wan Gerin Bikes, Wiseman Frameworks, and Platano Customs. A food truck, outdoor seating, and, of course, plenty of java created a fun atmosphere for checking out sweet rides and learning about the industry.

I asked Levi Borreson of Chicago-based Legacy Frameworks why the market for hand-built bicycle scene still hasn’t reached critical mass in Chicago. He argued that the flatness and relatively compact nature of our city means it’s so easy to get around by bike here that most cyclists don’t see the need for a high-performance steed, and our long winters and high bike theft rate discourages investments in premium cycles. “People don’t buy nice bikes and there is relatively no recognition of nice bikes.”

Due to these headwinds, frame building is generally done as a sideline, rather than a 9-to-5 in Chicago. But Borreson, who’s run Legacy for about six years, has been lucky enough to turn metal fabrication into a full-time job, allowing him to really concentrate on his projects. He specializes in upright city bikes, and while these may not be the lightest or fastest rides around, they’re built for comfort, durability, and ease of maintenance. Recently he began taking on apprentices work with him over the summer and learn shop skills and frame building. He also offers intensive two-week classes where individuals pay him to learn only frame building.

Doug Fattic who runs a frame-building school in Niles, Michigan, an hour-and-a-half ride from Chicago via Amtrak’s Wolverine line, showed up for the Heritage event. He offers education for would-be frame builders in the form of a three-week course, and several of the frame builders at the show have learned their craft from him. Fattic recommends the forum Velocipede Salon for both novice and professional frame builders who want to increase their knowledge. He has been biking and building since the late 1970s, and says he has no problem with giving his knowledge back to the community.

Noah Wangerin, one of Fattic’s former disciples, has gone on to open his own company in Chicago, Wan Gerin. His frames are distinguished by meticulously detailed lugs, the socket-like metal sleeves that hold the frame tubes together. He has also paid homage to classic Schwinn designs via the paint jobs and decals he employs, but he puts his own unique stamp on these models with ornate, 3D-printed stainless steel head tube badges.

Wangerin is optimistic about the future of bike builders and riders in Chicago. “I'd like for biking to feel more accessible to everyone," he said. "I think a big part of that is making riders feel safe in the city with proper planning and infrastructure. A bike saves you [time and money] on gas, traffic, parking, and a gym membership. If more people realize that and feel comfortable acting on it, I think more might be interested in a custom bike to get them to and from work. Money saved on gas, parking, etcetera is well over the cost of a custom bike that will last for years.”

Mike Patton, owner of Chicago-based Patton Frames works full-time as a manufacturing engineer and builds bikes on the side, as well as racing with the local team Bonkers Cycling. “I’ve gotten so much better [at building frames] since I started,” he said. “I’ve gotten to the point where I can just put them together. It takes me about four or five weeks for a frame. It isn’t my day job, so I could probably do it faster, but it’s just [a matter of] finding the time.” However, he hopes to devote more time to fabrication in the future.

Patton uses locally based Platano Customs, a bike and motorcycle painting service owned by his friend Brian Powell, for most of his builds. “[Brian] was sad when I said I wanted something basic for the bike I brought to the show,” Patton explained. “He has such a creative spirit. So I let him do some detailing his way inside of the fork.” From seeing Patton’s first-rate work in person at the show, you would expect him to charge more, but his prices are ridiculously reasonable compared to what some bigger bike companies charge for custom work.

Several of the Chicago bike builders present share a frame-building workspace called Bubbly Bicycle Works at the sustainable business incubator Bubbly Dymanics in Bridgeport. Bench space is available for $200 a month.

Although the Chicago Handmade Bicycle Show was small, the quality on display suggest that there will be productive and profitable future for local frame builders. In the last three years, more builders have emerged in the region as the demand for quality, bespoke bikes has increased.

A key thing holding back the local bike building industry seems to be a lack of exposure. If cyclists don’t know they have the option of ordering a bike made just for them, they will keep buying from larger distributors. Heritage took the initiative to get these builders out of the workshop and into the public eye. As word gets out about these talented people, I have no doubt we’ll see more Chicagoans on handmade rides. A robust frame-building community would give our city yet another reason to claim the best bike town crown.

Streetsblog Chicago will resume publication on Tuesday. Have a great Memorial Day weekend!